About Us

The Bott Shop brings you the full and extensive range of Bott's world leading workplace storage equipment. Bott products have been designed and manufactured in the UK for over 40 years.

Flexible Manufacturing

Bott have invested heavily in their manufacturing capability, enabling them to offer a comprehensive range combined with short lead times. From Work Benches to CNC Storage to Heavy Duty Cupboards, there is a Bott product to suit your needs regardless of the industry to are in.

About Bott

Bott have been manufacturing workplace storage equipment in the UK for over 40 years.

Bott’s modern, flexible manufacturing capability and modular design ethos enables them to make most products to order and offer a comprehensive range combined with short lead times.

As a business they have invested in technologies such as rainwater harvesting, energy efficient plant, solar power, intelligent lighting and waste stream recycling.

Logistics & Delivery

Bott have invested in developing their very own delivery fleet. Bott’s intensive transport service runs outbound deliveries of workshop equipment and incoming raw material logistics without relying on third parties. This ensures that that your item is delivered on time and in perfect condition.

Bott’s total transport fleet total more than 150 to 200 deliveries a week.

Our client list is growing…

Bott Shop continue to serve a growing sector of industries who rely on the best workplace storage solutions to organise their operational areas. We are proud to be a supplier to a wide range of clients including:

- Automotive

- Aerospace Manufacturers

- Aerodromes and Hangers

- Race Teams

- Manufacturers

- Nuclear

- Maintenance and Facilities

- Tool Rooms and Development Areas

- CNC Machine Shops

- Schools and Colleges

Product Design & Quality

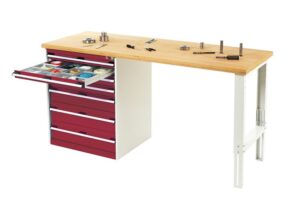

- Cubio drawer cabinets are very heavy duty with loads of up to 1 tonne UDL.

- The drawers run on robust roller bearing slides with 75kg capacity and 100% extension.

- Ergonomic drawer handles come complete with label holder and clear plastic cover.

- Fully powdered coated in a choice of 4 attractive colours

- All Bott products come with a 10 Year Guarantee

- Cubio drawer cabinets have central locking and come with a safety drawer blocking mechanism to prevent more than one drawer opening at a time.

- Can be used as part of a modular system, combining the drawer cabinets with cupboards, workbenches and a wide range of accessories to create your tailored solution.

About Bott

Wilhelm Bott founded a mechanical workshop in a mill near Gaildorf in 1930 – the nucleus of today’s Bott Group. As early as 1940, the company employs 70 people.

Today, the group employs around 950 people (2016) and generates annual sales of EUR 132 million (2016). Apart from the three production sites Germany, England and Hungary, the Bott Group currently has numerous subsidiaries in Europe as well as licensing partners and importers all over the world. Bott is the leading international manufacturer of vehicle equipment, workshop equipment and workstation systems.

Bott is certified to ISO 9001. Bott products also carry the GS symbol for TÜV approved safety. Bott is a manufacturer of high quality workplace and storage solutions. The Bott philosophy is based on total quality, rapid response, value for money and reliability.

Quality Policy

Bott Limited manufacture and distribute high quality storage equipment and workplace systems.

It is the policy of Bott Limited to ensure that each contract is executed and fulfilled in a manner that is consistent with fully meeting the requirements and specifications of the customer.

The Company’s reputation is built around the key service criteria of Total Quality, Rapid Response Times, Value for Money and Reliability. Quality objectives are continually reviewed and set in line with the company’s evolving strategic plan.

In order to support this policy, and the requirements of BS EN ISO 9001:2015, the Company has established and documented a formal Quality System that encompasses all functions within the organisation affecting quality. It is the responsibility of the Quality Manager to maintain the Quality System.

The Quality System is subject to regular audit and review in order to maintain its validity, and to ensure that the system supports the Company’s defined quality objectives. Areas for improvement are identified through specific non-conformances, trend analysis, employee suggestions, initiatives, audit results and customer feedback.

Bott are committed to looking after the environment and have invested in becoming ISO 14001 compliant. In addition Bott takes a proactive approach to further reducing their environmental impact.

Bott has installed solar arrays to generate a proportion of the energy required to support ongoing operations. As part of a recent factory extension the company has now installed further solar capacity, giving a total of 60KW of installed capacity.

Energy Saving

Bott recognises that improving efficiency makes both business and environmental sense and they have worked hard to introduce:

- An LED lighting system with intelligent controls to reduce electrical consumption

- Modern plant equipment, which is regularly maintained to ensure maximum efficiency

- Forced warm air recirculation from roof space to floor level

- A camel back paint plant oven which naturally reclaims heat to minimise energy input

- Cutting edge compressed air generation with variable speed drives for efficient fluid power systems

Bott’s energy committee actively looks for energy saving opportunities, enabling them to grow their output whilst minimising environmental impact.